Return

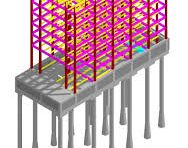

Flow Diagram

A Flow diagram is a diagram that shows the step-by-step flow of operation. To figure out the correct sequence of the process to get a solution for a problem.

A Flow diagram allows the site management to see the day-to-day flow of work. To see workflow improves the work performance.

The performance of civil engineering projects can improve. By allowing the site management to visualize. And to see the workflow on the construction site.

Even though the construction process is not standardized. It needs to be re-developed each time. The contractor’s focus is not to plan and optimize the on-site building process.

Visualization of flows in civil engineering projects. Such as housing construction, is more common.

A reason for this is the large variation in physical layout. And few standardized work task in traditional civil engineering projects.

Reducing on-site material handling. And lead times through proper workflow management. Is an important part of the construction industry’s improvement of productivity

Waste elimination is a focus for workflow improvement within Lean production.

The site management must learn to differentiate between value adding. And wasteful activities and cut waste from the construction process.

Waste as any human activity. Absorbs resources without creating any value. Like waiting time. Overproduction. Unnecessary inventory. Erroneous processes. Unnecessary movement and transports. Products with errors. And not meeting customer demands. Identified construction waste. As poor/incorrect quality of the product. Rework. Excessive and leftover materials. Material handling, materials in stock, and work in suboptimal conditions.

Seeing the potential of workflow improvements. Waste observed in the current state. Was the moving materials around the construction site. Waiting for materials, machines or instructions, rework, and interruptions of progressive work

Several productivity studies state. “that there is much waste generated on a construction site”. The key to improving on-site construction is in the management of the flow of materials. Resources and information. A standardized flow of materials. Makes it possible for the site management to plan ahead. Rather than “extinguish fires” (solve urgent matters).

Achieving the right flow of work in production processes is important. Decisions made early affects how, e.g. a bridge is to be built, and the effects the workflow on-site. Such factors as location. Type and shape, material choice and detail design all affect the flow of work.

To achieve workflow at the construction site. The design and planning phase needs to be controlled. Managed from a buildability perspective.

Proactive workflow management. Aims at removing hindrances to production workflow in the design phase. Common methods are e.g. improved buildability and proper production planning.

The benefits of improving lead times, reducing inventories and lowering manufacturing costs. Smaller Batches, Shorter lead times. Less material handling. Increased production. Project on-time. More projects with same resources. Increased profitability. Increase delivery performance. Fewer inventories. Less operational costs.Less safety stock. Faster inventory turnover.

Straight-forward improvements to workflow. Introduce the improvements slowly. Then check the process response. Finally, an ideal state is attained. Which reactive and proactive solutions to workflow are implemented.